Fibers for Static Dissipative Applications

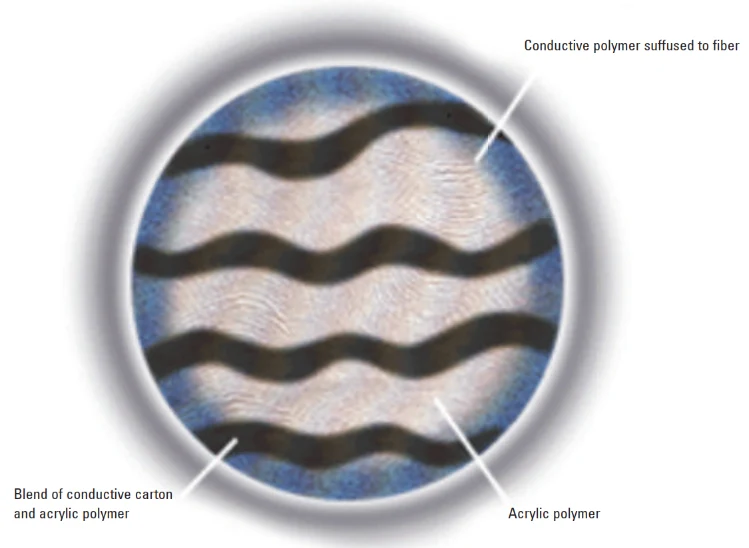

A conductive fiber designed to control static electricity.

PRIMARY USE: Ideal for static dissipative applications, preventing static buildup in sensitive environments.

The Conductrol™ fiber from Sterling is specifically developed to control electrostatic discharge (ESD). ESD poses risks in industries like filtration, where a spark could trigger a dust explosion. Conductrol™ fibers blend the stability of carbon-based fibers with enhanced electrostatic performance and are used in filtration products, carpet backing, upholstery, and specialty materials like adhesives and epoxy flooring. The conductivity of these fibers is stable over the product’s lifetime, offering consistent protection. Available as a staple fiber in a wide range of cut lengths.

Fibers for Non-Asbestos Gaskets

Sterling’s acrylic (PAN) fibers and pulps provide cost-effective alternatives, offering improved tensile strength, flexibility, heat resistance, and processability in gaskets. Available in various forms—fibrillated fibers, short-cut fibers, and engineered blends—these fibers enhance gasket performance, prevent mix segregation, and solve common processing issues like fiber balling

| Sterling Technical Fibers for Non-Asbestos Gaskets | ||

|---|---|---|

| Fiber Type | Description | Applications |

| CFF 106-3 Fibrillated Fiber | Acrylic pulp, wet, CSF = 600, 6.5 mm nominal length | Beater Addition Gaskets, Resin Impregnated Papers |

| CFF 111-3 Fibrillated Fiber | Acrylic pulp, wet, CSF = 250 ml, 6 mm nominal length | Beater Addition Gaskets, Resin Impregnated Papers |

| CTF 311 Technical Fiber | Acrylic fiber, 10 micron diameter, 1-2 mm length | Beater Addition, Compressed Sheet, Formed-in-Place Gaskets |

| CTF 525 Technical Fiber | Higher heat resistant acrylic fiber, 12 micron diameter, 1-2 mm length | Beater Addition, Compressed Sheet, Formed-in-Place Gaskets |

| CPF 406 Fiber Blend | Engineered Blend of CTF 525 Technical Fiber(3 mm) and CFF Pulp | Compressed Sheet, Designed to Solve Mixing Problems in Some Processes Where Fiber Balling /Pilling Can Occur or Where the Use of Longer Fiber Is Desired. |

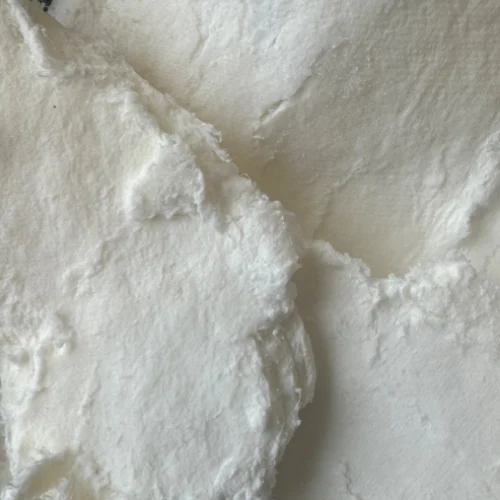

A fibrillated fiber that is processed into sheet form and retains moisture. Unlike wet pulp, wet lap is not shredded but instead delivered as a semi-continuous sheet.

PRIMARY USE: Ideal for wet mixing operations, such as in filtration and specialty paper applications. The moisture content in the sheets helps with integration in water-based or slurry processes.

Similar in fiber composition to wet lap, wet pulp is a fibrillated fiber that is shredded and retains water.

PRIMARY USE: Also suited for wet mixing operations like filtration and specialty papers, wet pulp’s shredded form allows for easy dispersion in water-based processes and applications that need a high degree of binding

A short-cut fiber processed with crimp, allowing improved interlocking and more bulk.

PRIMARY USE: Also suited for gaskets and stucco applications, where the crimped structure enhances bonding and reinforcement.

A short-cut, straight fiber with no bends or waves, ideal for applications needing reinforcement without added texture.

PRIMARY USE: Also suited for gaskets and stucco applications, where the crimped structure enhances bonding and reinforcement.

CFF 100 Series Fibrillated Fibers: Made from standard polymer and offered in a range of Canadian Standard Freeness, or degree of fibrillation, to meet the customer’s requirements.

CTF 311 Technical Fiber – made from standard polymer, offering a cost-effective solution for moderate temperature applications.

CTF 525 Technical Fibers: Designed for higher temperature resistance and higher strength applications.

CPF 406 Fiber Blend: An engineered blend to tackle fiber balling and improve uniformity in compressed gaskets.