Fibers for Friction Materials

Sterling Fibers is the technology leader for engineered fibers and pulps that are explicitly designed to provide innovative solutions for various requirements and processes in the non-asbestos friction material industry.

| Application | Function | Product Form | Products Available |

|---|---|---|---|

| Automotive Disc Pads / Truck Blocks / Linings (Dry Mixed) | Combined Preform Strength / Mix Homogeneity / Friction Stability | Dry Pulp | CFF V110-1, CPF 200 series |

| Automotive Disc Pads / Truck Blocks / Linings (Dry Mixed) | Mix Homogeneity Processing | Dry Pulp | CFF V125-1 |

| Automotive Disc Pads / Truck Blocks / Linings (Dry Mixed) | Short Fiber Processing / Reinforcement | Dry Pulp / Fiber Blends | CPF 400 series |

| Friction Papers | Paper Web Formation / Binding / Controlled Paper Porosity | Wet Pulp | CFF 100 series CFF 500 series |

| Roll Linings / Segments / Wet Resin Mixes | Processing / Crack Resistance / Fracture Toughness | Short Cut Staple Fiber | CTF 395, CTF 525 |

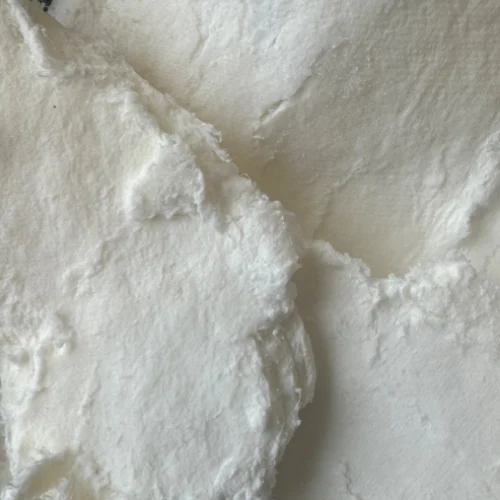

A fibrillated fiber product with no water content. This makes it suitable for applications where water is not ideal for processing.

PRIMARY USE: Dry mixing operations for products like friction materials. Its dry nature allows it to blend easily with other materials without introducing moisture.

A fibrillated fiber that is processed into sheet form and retains moisture. Unlike wet pulp, wet lap is not shredded but instead delivered as a semi-continuous sheet.

PRIMARY USE: Ideal for wet mixing operations, such as in filtration and specialty paper applications. The moisture content in the sheets helps with integration in water-based or slurry processes.

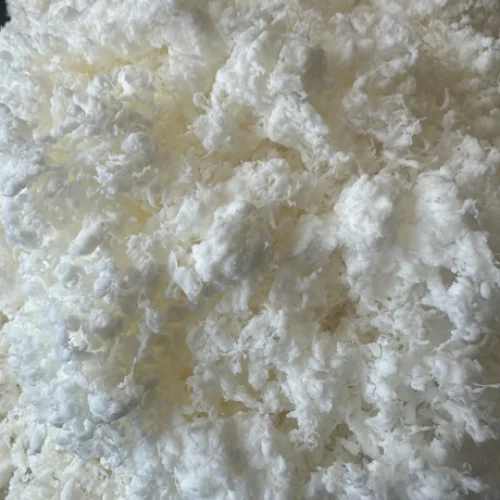

Similar in fiber composition to wet lap, wet pulp is a fibrillated fiber that is shredded and retains water.

PRIMARY USE: Also suited for wet mixing operations like filtration and specialty papers, wet pulp’s shredded form allows for easy dispersion in water-based processes and applications that need a high degree of binding

A short-cut fiber processed with crimp, allowing improved interlocking and more bulk.

PRIMARY USE: Also suited for gaskets and stucco applications, where the crimped structure enhances bonding and reinforcement.

A short-cut, straight fiber with no bends or waves, ideal for applications needing reinforcement without added texture.

PRIMARY USE: Also suited for gaskets and stucco applications, where the crimped structure enhances bonding and reinforcement.

CFF V110-1 Fibrillated Fiber (PAN Pulp) – Flagship product, equivalent performance to Aramid at a lower cost.

CPF 200 Series – Economical alternative to CFF V110-1.

CFF V125-1 – Shorter fiber than CFF V110-1.

CPF 400 Series Fibers – Acrylic pulp blended with reinforcing fibers like melamine, fiberglass, carbon, and basalt to prevent balling in dry-mixed formulations.

CFF 111 Series – Wet pulp from standard polymer for friction papers. Products include CFF 106, CFF 111 and CFF 114.

CFF 500 Series – Wet pulp from high modulus, high tenacity second generation polymer for friction papers.

CTF 395 Short Cut Staple Fiber – Cost-effective reinforcement solution from standard polymer with excellent adhesion to phenolic resins.

CTF 525 Short Cut Staple Fiber – High tenacity, high modulus acrylic fiber from second generation polymer engineered to absorb crack energy.