Sterling Fibers’ CFF® acrylic pulp is engineered for specialty wet-laid and slurry applications, including papers, filter media, speaker cones, and nonwovens. This fibrillated fiber pulp is designed to act as a high-efficiency binder, enhancing specialty composites’ structural integrity and performance. The unique pulp architecture is achieved through a proprietary process, allowing for precise control over fiber length and fibrillation. Offered in a range of Canadian Standard Freeness, or degree of fibrillation, to be engineered to meet each customer’s specific requirements.

| Sterling Technical Fibers for Specialty Papers / Filtration | ||

|---|---|---|

| Fiber Type | Description | Form |

| CFF 106 Fibrillated Fiber | Acrylic pulp, wet, CSF = 600 ml, 6.5 mm nominal length | Available as wet lap or wet pulp 25 – 30% solids |

| CFF 111 Fibrillated Fiber | Acrylic pulp, wet, CSF = 250 ml, 6 mm nominal length | Available as wet lap or wet pulp 25 – 30% solids |

| CFF 114 Fibrillated Fiber | Acrylic pulp, wet, CSF = 60 ml, 6 mm nominal length | Available as wet lap or wet pulp 25 – 30% solids |

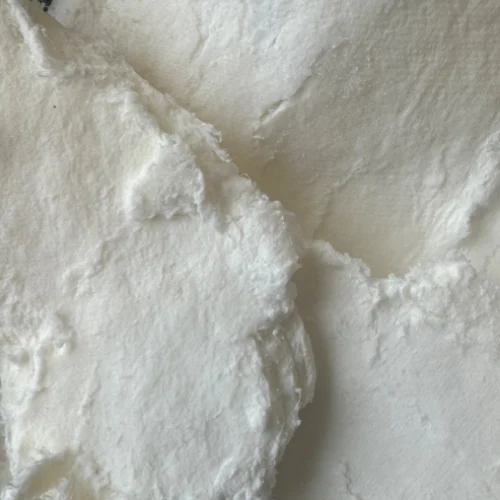

A fibrillated fiber that is processed into sheet form and retains moisture. Unlike wet pulp, wet lap is not shredded but instead delivered as a semi-continuous sheet.

PRIMARY USE: Ideal for wet mixing operations, such as in filtration and specialty paper applications. The moisture content in the sheets helps with integration in water-based or slurry processes.

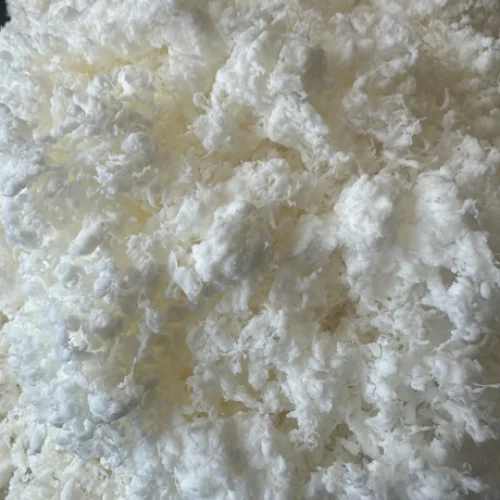

Similar in fiber composition to wet lap, wet pulp is a fibrillated fiber that is shredded and retains water.

PRIMARY USE: Also suited for wet mixing operations like filtration and specialty papers, wet pulp’s shredded form allows for easy dispersion in water-based processes and applications that need a high degree of binding