Static Dissipative Applications

Conductrol™ is a uniquely engineered acrylic based fiber for the control of electrostatic discharge that combines the stability of carbon-based fibers with the enhanced performance of modified fibers.

Electrostatic Discharge, referred to as ESD, is the phenomena of that uncomfortable spark you see and feel after you walk across a carpet and touch a doorknob. In certain environments such as solids/air filtration, a single spark has the potential to set off an explosion. Therefore, control of ESD is required in many different industries.

Electrostatic Discharge, referred to as ESD, is the phenomena of that uncomfortable spark you see and feel after you walk across a carpet and touch a doorknob. In certain environments such as solids/air filtration, a single spark has the potential to set off an explosion. Therefore, control of ESD is required in many different industries.

Conductrol™ can be incorporated into:

- Filtration products, woven and non woven

- Carpet backing: needle punched, woven scrim

- Upholstery: spun yarns incorporated into fabrics

- Apparel: spun yarns for woven or staple for non woven fabrics

- Specialty Materials: short staple incorporated into mediums such as adhesives, rubber and epoxy flooring.

The blend level ratio in the above applications may be adjusted to give the desired level of conductivity.

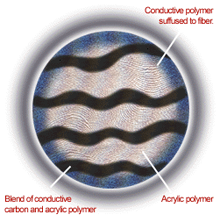

The cross section of this revolutionary patented fiber shows how the polymer is suffused to the fiber, resulting in a highly stable conductive product. Conductivity will remain constant over the life of the product.

The cross section of this revolutionary patented fiber shows how the polymer is suffused to the fiber, resulting in a highly stable conductive product. Conductivity will remain constant over the life of the product.

The resultant fiber, Conductrol™, is very durable.

| PH3-11, room temp | no effect |

| Laundering | no effect, 75 launderings |

| Floor cleaners and detergents | no effect |

| Chlorine bleach | 3x10 to the 6th after 36 hours in concentrated bleach |

| Thermal aging ,170 degrees C | no effect after 10 days |

Conductrol's typical properties are:

| Denier | 3.0 |

| Length | 1.0-150mm |

| Color | black |

| Resistivity | 1.0 x 10 to the 5th ohm/in/fil |

| Tenacity (g/den) | 3.0-3.5 |

| Elongation(%) | 25-35 |

| Crimps per inch | 12-14 |

| Percent Crimp | 12-14 |

For more information contact the Technical Fibers Group at 1-800-342-3779 or Contact us.